Facility

FacilityFACILITY

Production equipment

| Construction | Equipment photo | Features | Maximum diameter |

|---|---|---|---|

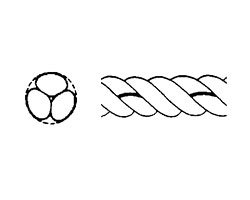

Twisted Ropes |

|

This equipment is used to produce twisted ropes such as 3-strand ropes, 4-strand ropes and 6-strand ropes. From nylon ranger ropes for rescues to side ropes for fixed nets and draglines for bottom trawls, we use our unique rope-making technology to provide high-quality products that meet the needs of our customers. | φ100mm |

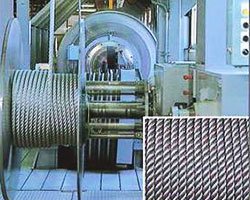

8-Strand Ropes |

|

This equipment is used to produce 8-strand ropes, which consist of a total of 8 strands: four Z-twist strands and four S-twist strands. We have designed and developed our own "TOSCO Machine" to produce these 8-strand ropes. The large machine can produce 8-strand ropes with a diameter of 160 mm, making it one of the largest of its type in the world. The main feature of the TOSCO Machines is that the strands are braided into the ropes with a consistent twist, producing a uniform twist over the entire length of the rope. | φ160mm |

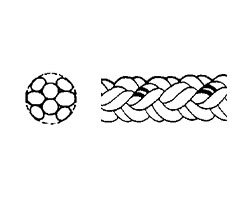

Twell Ropes (12-Strand Ropes) |

|

This equipment is used to produce our Twell ropes (12-strand Ⓡropes), which consist of a total of 12 strands: six Z-twist strands and six S-twist strands. Twell ropes are a high performance rope with a 12-strand structure, high strength and low elongation, developed with our unique, in-house technology. One of the largest in Japan, our large braiding machine can produce ropes up to 180 mm in diameter, making it possible to meet a wide variety of needs, including thick and long ropes. Twell is a registered trademark of TOKYO SEIKO ROPE MFG.CO., LTD. | φ185mm |

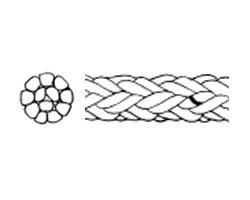

Double Braid Ropes |

|

This equipment is used to produce double braid ropes (Toughlay Ⓡ), which have a double structure that allows synthetic fibers to exhibit more of their natural strength and significantly reduces elongation at rope break. We have also introduced equipment that can produce ropes up to 300 mm in diameter, making it possible to meet a variety of needs, including thick and long ropes. Toughlay is a registered trademark of TOKYO SEIKO ROPE MFG.CO., LTD.> | φ300mm |

| Coated Ropes |  |

For applications that require insulation, weather resistance, abrasion resistance, chemical resistance, etc., fiber ropes can be coated with a variety of resins (please contact us for information on our range of resins). | Please contact us |

| Heat Set Machine |  |

This machine is used for the heat setting (heat treatment) of fiber ropes while applying the appropriate load. By heat setting fiber ropes, the rope structure of both twisted and braided ropes becomes more stable and easier to handle. | Please contact us |

Equipment

| Testing machine | Features | |

|---|---|---|

| 5000 kN Horizontal Tensile Testing Machine |  |

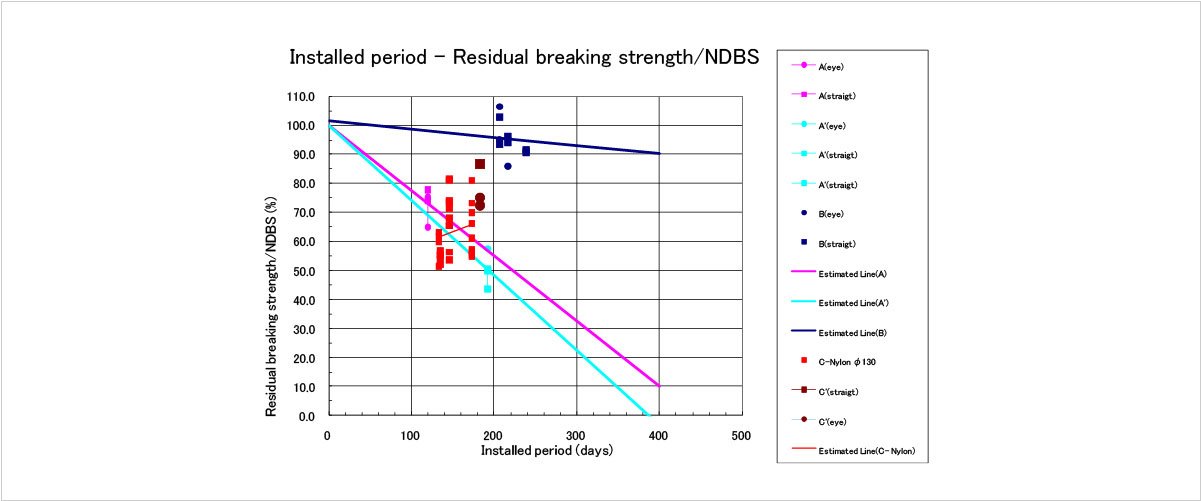

In 1991, we introduced a 5000 kN horizontal tensile testing machine, the largest in Japan for fiber rope at the time into out testing room. In addition to the tensile testing of new ropes, we also offer a rope replacement cycle where we test the residual strength of ropes that have been used by our customers. In addition, our tensile testing machine is calibrated every year by the Nippon Kaiji Kyokai (Japan Maritime Association), and has maintained the same measurement accuracy since its introduction. |

| Large Fatigue Testing Machine |  |

We evaluate the durability of ropes in terms of tensile fatigue caused by repeated loading and bending fatigue caused by repeatedly passing through sheaves. We also contribute to the development of ropes by changing loads and the standard of sheave diameters. |

| Yarn-on-Yarn Testing Machine |  |

This machine is used for evaluating the abrasion resistance of yarns according to the [CI 1503] standard. It is possible to evaluate the abrasion resistance of materials used in yarn by twisting the yarn together while applying a set amount of tension to it. |

| Abrasion Testing Machine | Different from the Yarn-on-Yarn Testing Machine, this machine evaluates the abrasion resistance of the rope itself. The rope is passed through the grinder a set number of times while rotating to evaluate surface wear and residual strength. (Conformity to NK standard) |

|

※Other testing machines are also available, so please do not hesitate to contact us with any requests or questions.

Exam service etc.

There are no official replacement standards for textile ropes. Since the degree of aging deterioration changes depending on the intended use and usage environment, it is recommended to perform a destructive test to predict the aging deterioration trend and determine the number of years of use. We use 5000kN destructive test equipment to help our customers.

Processing related

Processing that meets various requests is possible.

SBM processing yard and processing landscape

Other processing scenery, stationary, etc.